Carbon fiber repair involves a series of precise steps to restore damaged components to their original strength and appearance. This step-by-step guide outlines the entire repair process, from assessing the damage to final inspection, providing detailed instructions for each stage. Whether you’re a seasoned professional or new to carbon fiber repair, this guide will help you achieve high-quality results.

Assessing the Damage

The first step in any repair is to assess the extent of the damage. This involves a detailed inspection and documentation of the affected area. Visual inspection can reveal obvious signs of damage such as cracks, delamination, and surface scratches. Advanced diagnostic tools, such as ultrasound or thermography, can detect hidden damage that is not visible to the naked eye. Understanding the full extent of the damage is crucial for planning the repair.

Preparing the Area

Once the damage has been assessed, the next step is to prepare the area for repair. This involves cleaning the damaged area to remove any dirt, grease, or loose fibers. Sanding the area creates a smooth surface for the repair materials to adhere to. Masking off the surrounding areas with tape protects them from resin and dust during the repair process.

Cutting the Fabric

Accurate measurement and cutting of the carbon fiber fabric are essential for a successful repair. The fabric should be cut to the correct size and shape to cover the damaged area completely. Using a rotary cutter or sharp scissors ensures clean, precise cuts. For complex shapes, templates can be used to achieve the desired contours.

Mixing the Resin

Choosing the right resin is crucial for a strong bond. Epoxy resin is commonly used for carbon fiber repair due to its excellent adhesion and durability. Proper mixing of the resin is essential to ensure consistent properties throughout the repair. Follow the manufacturer’s instructions for the correct ratio of resin to hardener and mix thoroughly to avoid air bubbles.

Applying the Fabric and Resin

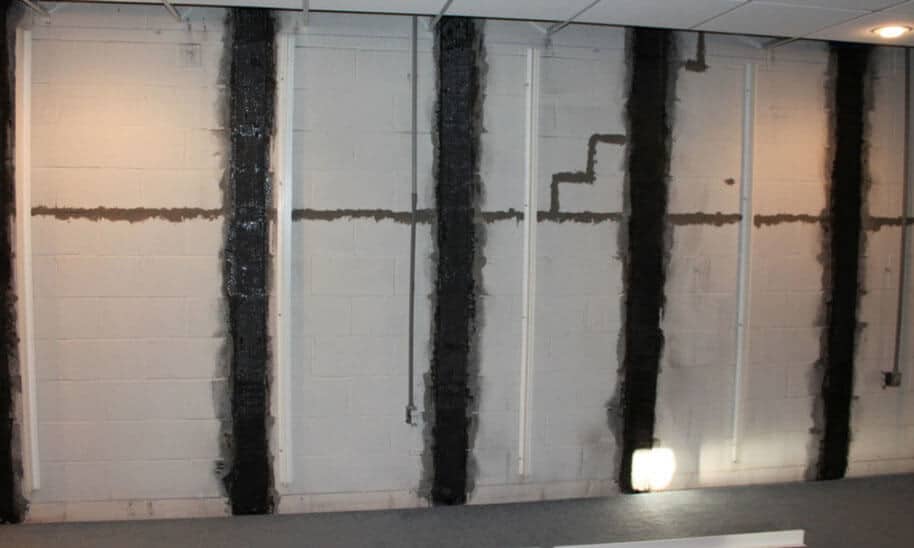

The next step is to apply the carbon fiber fabric and resin to the damaged area. Start by applying a thin layer of resin to the prepared surface. Place the fabric over the resin and use a roller or brush to saturate it completely. Layering techniques can be used to build up multiple layers of fabric for added strength. Ensure each layer is fully saturated with resin before applying the next one.

Curing the Repair

Curing the repair is a critical step that determines the final strength and durability of the repair. Different curing methods can be used, including room temperature curing, heat curing, and vacuum bagging. Vacuum bagging involves placing the repair under a vacuum-sealed bag and applying pressure to remove air bubbles and ensure even resin distribution. Autoclave curing uses high pressure and temperature to achieve the best possible bond.

Finishing Touches

After curing, the repaired area needs to be finished to match the surrounding surface. This involves sanding the repair to remove any rough edges and create a smooth finish. Protective coatings can be applied to enhance the durability and appearance of the repair. These coatings also protect the repaired area from environmental factors such as UV light and moisture.

Final Inspection and Testing

The final step is to inspect and test the repair to ensure it meets the required standards. Visual inspection checks for any remaining flaws or imperfections. Structural testing, such as flexural or tensile tests, verifies the strength of the repair. Non-destructive testing methods, such as ultrasound, can be used to check for internal defects. Ensuring the repair is done correctly is crucial for the longevity and performance of the carbon fiber component.

Carbon fiber repair is a meticulous process that requires attention to detail and the use of appropriate techniques and materials. By following this step-by-step guide, you can achieve high-quality repairs that restore the strength and appearance of damaged carbon fiber components. From assessing the damage to final inspection, each step is crucial for a successful repair. With practice and experience, you can master the art of carbon fiber repair and ensure the longevity and performance of your components.

Contact the Professionals at StablWall Today (866) 782-5955