Across the U.S., owners and agencies are trying to extend the life of buildings, parking garages, bridges, and critical infrastructure. Even when replacement is the long-term plan, repairs often need to happen now.

ASCE’s 2025 Report Card gave U.S. infrastructure an overall grade of C and highlighted a projected $3.7 trillion investment gap between planned spending and what’s needed to reach good condition. At the same time, reporting based on FHWA data shows tens of thousands of bridges remain in “poor” condition nationally.

This is the environment where structural strengthening systems, including carbon fiber FRP (fiber-reinforced polymer), become especially relevant: they can reinforce without shutting down an entire facility for long demolition timelines.

What StablWall is, in plain terms

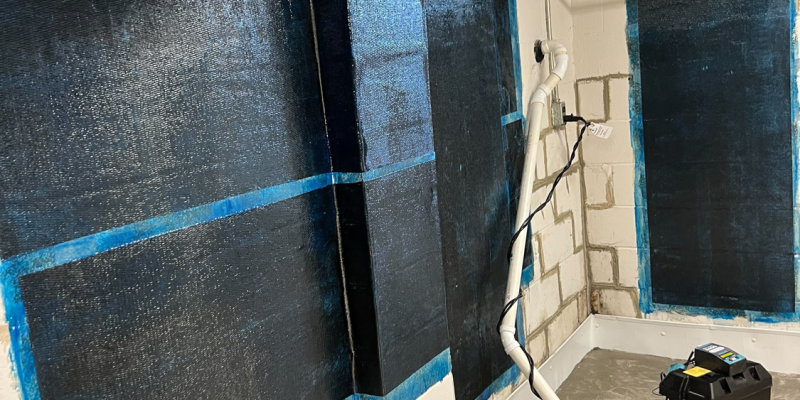

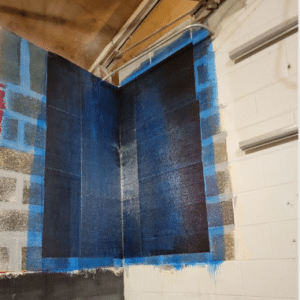

StablWall describes its system as carbon fiber sheets bonded with engineered adhesives, forming a composite that becomes one with the structure through a chemical reaction. They state the finished product becomes ten times stronger than steel.

They also emphasize versatility: the system can be applied in different patterns depending on the structural need (horizontal, vertical, stair-step, corner wrap).

Code and spec credibility: ICC-ES ESR-4424

StablWall’s Commercial page explicitly states the system is ICC Approved (ESR-4424) and DOT Approved in multiple states.

Their ICC-ES evaluation report (ESR-4424 Renewed 2025) describes the system as an externally bonded carbon fiber FRP composite and notes compliance evaluation with the 2021 and 2018 IBC and IRC. It also describes the product as externally bonded carbon fiber-reinforced polymer composites applied to unreinforced masonry substrates.

From a marketing standpoint, this is huge: it allows your blog to speak to engineers, facility managers, and specifiers with real documentation behind the claims.

Commercial applications: where StablWall positions the system

StablWall lists multiple commercial use cases, including:

exterior reinforcement of commercial buildings

high-rise buildings

bridge columns and rehabilitation

parking garages

outdoor retaining walls

pilaster repair

airports

That list is a ready-made SEO section because each bullet can become its own supporting paragraph, and each can become its own future blog post targeting long-tail keywords like “parking garage concrete reinforcement” or “pilaster stabilization carbon fiber.”

Civil infrastructure applications: bridge columns, beams, and porous surfaces

On the Civil Infrastructure page, StablWall highlights that the system can be installed on anything porous, and specifically calls out civil applications like:

bridge columns

box beams

any concrete or porous surface

They also state they have “over 40 years” in the structural repair business and that their carbon fiber “out performs other carbon fiber materials” while being “thinner than a dime.”

Separately, their Civil page frames the contractor value proposition: it’s intended for structural problems in parking garages, bridge columns, girders, piers, box beams, and other porous structures, and they emphasize installation is fast and permanent.

Why carbon fiber FRP makes sense in public and high-traffic environments

Commercial and civil repairs have constraints residential jobs don’t:

safety and load considerations

owner expectations for longevity

public visibility and compliance

Carbon fiber reinforcement is often selected because it can add strength without adding bulky components that steal usable space or create long-term maintenance headaches.

In their ICC-ES report, the StablWall system is described as a method to externally strengthen existing unreinforced masonry walls for out-of-plane flexural strength. That kind of strengthening approach aligns with real-world needs: reinforcement without full replacement.

A quick reality check on bridges and infrastructure

StablWall’s Civil Infrastructure page references ASCE’s 2013 report card and mentions “more than 66,000 bridges” as structurally deficient, using it to explain why agencies need repair alternatives.

To keep your blog current, pair that with recent reporting showing over 40,000 bridges still rated “poor” nationally (based on FHWA-related reporting). The key message remains consistent: the need is ongoing, and strengthening solutions matter.

Implementation talking points you can use in SEO content

Here are conversion-friendly points pulled from StablWall’s own positioning (great for H2/H3 sections and snippet optimization):

ICC Approved (ESR-4424) for spec confidence

DOT Approved in multiple states for transportation-related stakeholders

Thin as a dime for minimal profile impact

Fast install, quick curing, “finish the job and get onto the next one” for contractors

FAQs

What does “ICC Approved (ESR-4424)” mean for a project?

It indicates the system has an ICC-ES evaluation report describing uses, conditions, and code references (IBC/IRC). Project approval still depends on jurisdiction and design requirements.

Where can carbon fiber reinforcement be used?

StablWall markets use across commercial buildings, parking garages, retaining walls, bridge columns, airports, and other porous structures.

Why do agencies repair instead of replace?

ASCE has highlighted persistent investment gaps, and reporting shows many bridges remain in poor condition, so rehabilitation and strengthening are frequently used to extend service life.

Conclusion and CTA

For commercial and civil stakeholders, carbon fiber strengthening is not about “patching,” it’s about extending service life, improving safety, and reinforcing structures without unnecessary disruption. StablWall positions its system as ICC Approved (ESR-4424) and suited for a wide range of commercial and infrastructure applications, including bridge columns and parking garages.

If you want to spec the system, request information, or discuss project fit, StablWall directs users to call or use the online contact form.

Considering the serious implications of foundation problems, it’s clear that a proactive solution is needed. That’s where

Considering the serious implications of foundation problems, it’s clear that a proactive solution is needed. That’s where  Having applied

Having applied

Currently, researchers are working on ways to make carbon fiber even stronger and more durable. This could mean foundations that last considerably longer than they do now, saving you money on repairs and replacements. The future may also bring us carbon fiber that’s more resistant to the elements, reducing the risk of damage from natural disasters.

Currently, researchers are working on ways to make carbon fiber even stronger and more durable. This could mean foundations that last considerably longer than they do now, saving you money on repairs and replacements. The future may also bring us carbon fiber that’s more resistant to the elements, reducing the risk of damage from natural disasters.

When it comes to the structural strength of your home, nothing beats the power of StablWall. This revolutionary technology is designed to provide unparalleled protection against the most common foundation issues.

When it comes to the structural strength of your home, nothing beats the power of StablWall. This revolutionary technology is designed to provide unparalleled protection against the most common foundation issues. Low Energy Consumption: The manufacturing process of StablWall uses less energy compared to other similar products. This helps reduce greenhouse gas emissions contributing to global warming.

Low Energy Consumption: The manufacturing process of StablWall uses less energy compared to other similar products. This helps reduce greenhouse gas emissions contributing to global warming.