Foundation stability is critical to the safety and longevity of any building. Traditional repair methods, such as steel beams or wall anchors, have long been the standard. However, these approaches often require extensive labor and come with limitations. StablWall’s carbon fiber reinforcement system is reshaping the industry by offering a solution that is both effective and minimally invasive.

What is Carbon Fiber, and Why is it Ideal for Foundations?

Carbon fiber is a composite material known for its superior strength-to-weight ratio. It is made by weaving strands of carbon atoms into a fabric that is both strong and flexible. In the context of foundation repair, carbon fiber’s unique properties allow it to stabilize walls without adding significant weight or bulk.

Properties of Carbon Fiber:

High Tensile Strength: Carbon fiber can resist forces that would typically cause materials like concrete or steel to fail.

High Tensile Strength: Carbon fiber can resist forces that would typically cause materials like concrete or steel to fail.- Flexibility: Despite its strength, carbon fiber can conform to various wall shapes, making it versatile for different foundation types.

- Durability: Resistant to environmental factors like moisture, temperature changes, and corrosion, carbon fiber ensures long-lasting performance.

How Does StablWall Utilize Carbon Fiber?

StablWall has perfected the use of carbon fiber in foundation repair through its proprietary system. Unlike traditional reinforcements, which often involve heavy equipment and invasive techniques, StablWall focuses on simplicity and efficiency.

Step-by-Step Process:

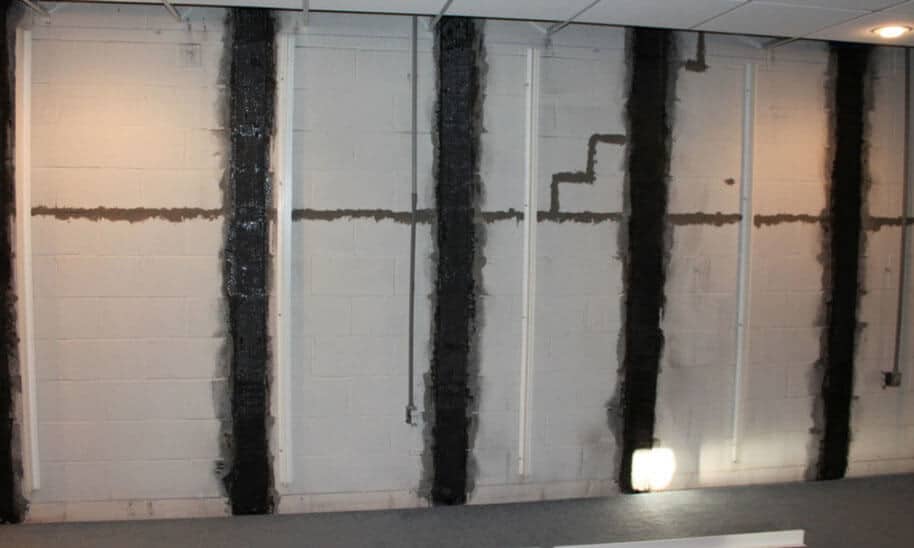

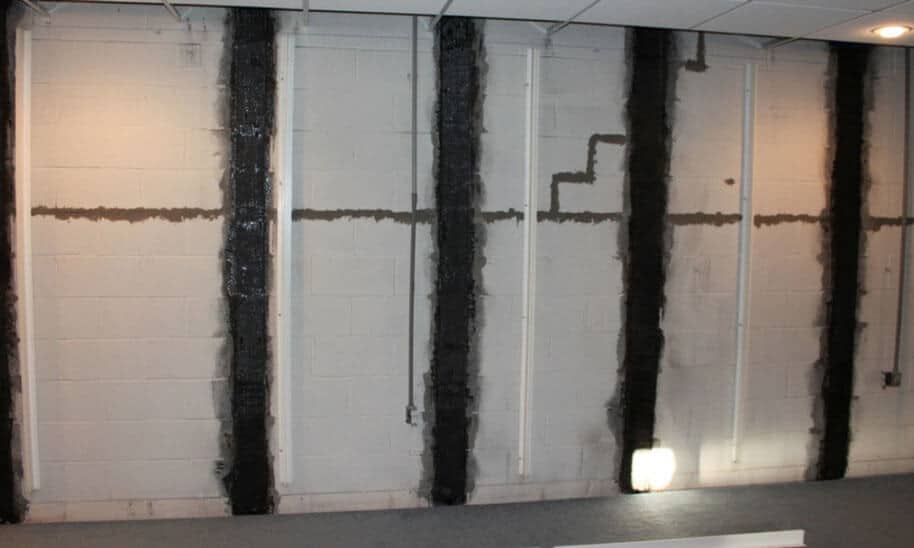

- Inspection: A foundation specialist evaluates the damage and determines the best placement for carbon fiber reinforcement.

- Preparation: The wall is cleaned to create an optimal surface for bonding.

- Application: A strong adhesive epoxy is spread over the wall, followed by the placement of StablWall’s carbon fiber sheet.

- Curing: As the epoxy cures, the carbon fiber bonds to the wall, creating a seamless and strong reinforcement.

Key Benefits of StablWall’s Approach

- Non-Invasive Repairs: Unlike wall anchors or steel beams, StablWall does not require excavation or major alterations to the home.

- Fast Installation: The process can often be completed in a single day, minimizing disruption for homeowners.

- Cost-Effective: With lower labor and material costs, StablWall offers an affordable alternative to traditional methods.

- Invisible Reinforcement: Once installed, the carbon fiber sheets are virtually undetectable, preserving the interior aesthetics of the basement.

Applications of StablWall

StablWall’s versatility makes it suitable for a range of foundation problems:

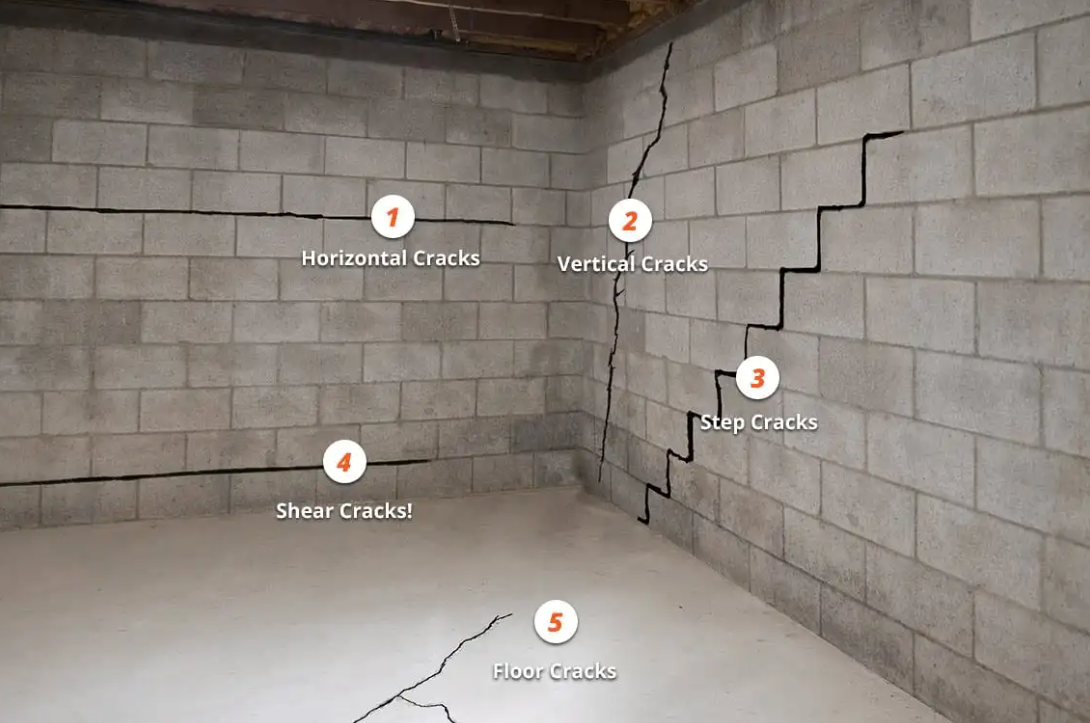

- Bowing Walls: By resisting lateral soil pressure, StablWall prevents walls from bowing inward.

- Horizontal and Vertical Cracks: The system stops crack propagation and restores wall integrity.

- Preventive Reinforcement: Even if no visible damage is present, StablWall can be installed as a preventive measure in high-risk areas.

Comparing StablWall to Other Methods

| Feature | StablWall Carbon Fiber | Steel Beams | Wall Anchors |

| Installation Time | 1-2 Days | Several Days | Several Days |

| Invasiveness | Minimal | Moderate | High |

| Cost | Affordable | Expensive | Moderate |

| Aesthetic Impact | Invisible Reinforcement | Visible Metal Beams | Visible Anchor Plates |

StablWall’s Commitment to Long-Term Solutions

One of the standout features of StablWall is its focus on longevity. The materials used are designed to withstand decades of wear and environmental challenges. This ensures that homeowners won’t have to revisit the same foundation issues in the future.

Additionally, StablWall integrates seamlessly with waterproofing systems, enhancing the overall durability and functionality of the foundation. This combination makes it a go-to choice for contractors aiming to deliver comprehensive solutions.

Why Choose StablWall?

For homeowners dealing with foundation problems, the decision often comes down to finding a solution that is reliable, cost-effective, and minimally invasive. StablWall checks all these boxes, offering a modern alternative to traditional methods. Its proven track record and growing popularity are a testament to its effectiveness.

StablWall is more than just a foundation repair system—it is a commitment to quality and innovation. By harnessing the power of carbon fiber, this system provides homeowners with peace of mind, knowing their homes are protected against future structural challenges. Whether dealing with existing damage or looking for preventive measures, StablWall is a trusted choice for durable, efficient, and long-lasting foundation reinforcement.

Contact the Professionals at StablWall Today! (866) 782-5955