You might have heard about carbon fiber as a potential fix for bowing walls, but how much do you really know about it? This high-strength material can be a game-changer for homeowners dealing with this common issue, offering a blend of durability and aesthetics that traditional methods often can’t match. From understanding its unique properties, installation process, to the cost implications, it’s important to get the full picture before making a decision. So, ready to uncover the potential benefits and drawbacks of using carbon fiber for your bowing walls?

Key Takeaways

- Carbon fiber is a strong, lightweight material ideal for reinforcing bowing walls due to soil pressure.

- Installation is straightforward, requires minimal demolition, and is virtually maintenance-free post-installation.

- Costs for carbon fiber repairs typically range between $4,000 to $12,000, depending on wall condition and size.

- Compared to traditional methods, carbon fiber installation is less invasive, faster, and provides a long-lasting, aesthetically pleasing solution.

- When choosing an installer, consider recommendations, online reviews, credentials, and obtain multiple cost estimates.

Understanding Bowing Walls

Battling bowing walls in your home can be a stressful experience. You’re not alone. Many homeowners face this issue at some point.

Bowing walls occur when there’s excessive pressure on your basement walls, usually from the surrounding soil. It’s not something to ignore. Left untreated, it can lead to serious structural damage.

You might wonder what causes this pressure. It could be from soil expansion due to excessive moisture, or perhaps your home was built on expansive clay. Even normal ground pressure can cause walls to bow over time.

Now, you’re probably thinking, “How do I identify a bowing wall?” They’re often characterized by horizontal or stair-step cracks. You might notice your doors or windows sticking, or perhaps the walls are visibly leaning or bulging. If you see any of these signs, it’s time to take action.

Don’t panic. There are effective solutions available. One such solution is carbon fiber, a popular choice for many homeowners.

But before we explore the details of carbon fiber, it’s important to understand the problem you’re dealing with. Bowing walls can be intimidating, but with knowledge and the right tools, you can tackle this issue head-on.

What Is Carbon Fiber?

You might be wondering, “What is carbon fiber?”

Well, it’s a lightweight, strong material made from thin strands of carbon atoms.

Let’s talk about its properties and why it’s considered an ideal fix for your bowing walls.

Understanding Carbon Fiber

The term “carbon fiber” might seem complex, but it’s actually quite straightforward.

It’s a material made from tiny strands of carbon, even smaller than human hair. These strands are woven together to form a fabric. This fabric is then combined with a plastic polymer resin to create a composite material that’s incredibly strong and lightweight.

Think of it like this:

- Imagine a single strand of hair. That’s roughly the size of one carbon fiber strand.

- Now, picture thousands of these strands woven together to form a fabric. That’s the carbon fiber cloth.

- Envision this fabric being soaked in a plastic polymer resin. It’s like dipping a cloth in glue.

- Finally, imagine this resin-hardened fabric being used to reinforce and strengthen structures. That’s carbon fiber in action.

Carbon Fiber’s Properties

Let’s explore the unique properties of carbon fiber to better understand its strength and versatility. Carbon fiber, a polymer, is extremely strong and lightweight. It’s five times stronger than steel, yet it weighs about two-thirds less. This makes it ideal for structural applications where strength and minimal weight are vital.

The properties of carbon fiber don’t stop there. It’s also resistant to corrosion, unlike metals that rust over time. Carbon fiber doesn’t degrade or lose its strength when exposed to harsh weather, which makes it ideal for use in your home’s foundational walls.

Here’s a quick comparison table to illustrate the advantages of carbon fiber over traditional materials:

| Property | Carbon Fiber | Traditional Materials |

|---|---|---|

| Strength | 5x of Steel | Varies |

| Weight | Light | Heavy |

| Durability | Resistant to Corrosion | Prone to Rusting |

| Weather Resistance | High | Varies |

Considering these properties, carbon fiber strips can provide the reinforcement needed for bowing walls. They’re a durable, effective, and long-term solution. With the proper installation, you’ll bolster your home’s structural integrity for years to come.

The Strength of Carbon Fiber

Harnessing the power of carbon fiber for bowing walls, we explore its impressive strength. You might wonder, ‘How powerful can it really be?’ Well, let’s investigate the specifics.

- Tensile Strength: Carbon fiber boasts a tensile strength that’s five times that of steel. That means it can withstand five times as much stretching force before breaking or deforming.

- Lightweight: Despite its strength, carbon fiber is incredibly light. It’s about 70% lighter than steel, helping to eliminate unnecessary strain on your walls.

- Non-Corrosive: Unlike metal, carbon fiber doesn’t corrode or rust. It maintains its strength over time, even in wet or damp conditions.

- Thermal Expansion: Carbon fiber has a minimal coefficient of thermal expansion. That’s a fancy way of saying it doesn’t expand or contract as much with temperature changes, maintaining its shape and strength in all sorts of environments.

Why Use Carbon Fiber for Bowing Walls?

Understanding the strength and durability of carbon fiber, it’s easy to see why it’s a prime candidate for treating bowing walls. But there’s more to it than that.

The unique properties of carbon fiber make it ideal for this purpose. One of its key benefits is its high tensile strength. This means it can withstand a lot of pressure without breaking, which is essential when dealing with the force exerted by a bowing wall.

Carbon fiber also doesn’t rust or corrode, so you don’t have to worry about it weakening over time due to exposure to moisture. Unlike some materials, it won’t degrade and lose its effectiveness, ensuring your walls remain secure for years to come.

Another advantage is that carbon fiber is lightweight. Despite its strength, it’s not bulky or cumbersome to work with. This makes the process of reinforcing your walls less labor-intensive and more manageable.

Lastly, carbon fiber is easy to install. It doesn’t require extensive demolition or reconstruction of your walls, which saves you time, money, and a lot of hassle.

In short, carbon fiber offers a durable, efficient, and practical solution for bowing walls. It’s worth considering if you’re dealing with this problem in your home.

Carbon Fiber vs. Traditional Methods

You might be wondering how carbon fiber stacks up against traditional methods of repairing bowing walls.

Let’s take a moment to compare these repair techniques, focusing particularly on the benefits of carbon fiber.

Understanding these differences can help you make an informed decision about the best solution for your project.

Comparing Repair Techniques

When it comes to repairing bowing walls, we need to compare two prevalent techniques: carbon fiber and traditional methods.

- First, let’s talk about the time factor. Traditional methods, like wall anchors or steel I-beams, can take days to install.

With carbon fiber, you’re looking at a few hours. Time is money, and you’ll save both with carbon fiber.

- Next, consider disruption. Traditional methods often mean digging up your yard or your basement floor.

Carbon fiber’s installation is far less invasive.

- Don’t forget about longevity. Steel can rust and deteriorate over time, but carbon fiber doesn’t.

It’s a solution that’ll last as long as your home does.

- Finally, think about finish. Steel beams stick out like a sore thumb.

Carbon fiber is sleek and can be painted over, blending into your home’s design.

Understanding Carbon Fiber

With all these comparisons in mind, let’s turn our attention to the specifics of carbon fiber as a method for fixing bowing walls. You may be wondering – what exactly is carbon fiber and how does it work?

Well, carbon fiber is a strong, lightweight material that’s used in a variety of applications, from automotive to aerospace, and yes, even home repair.

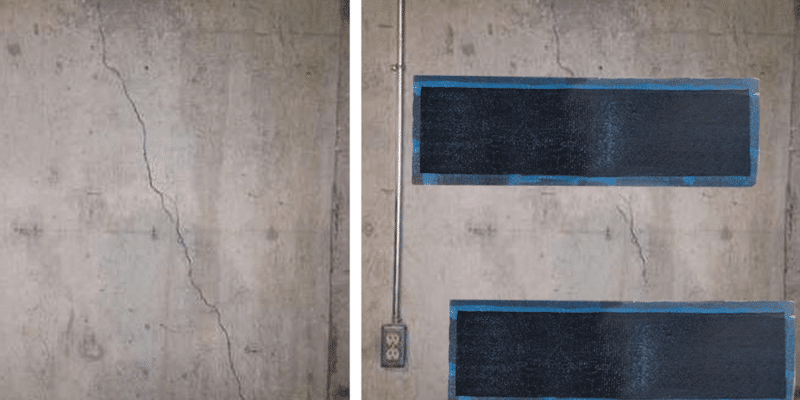

When it comes to bowing walls, carbon fiber is applied as strips along the wall’s surface. It’s then secured in place with an epoxy resin, creating a bond that’s strong enough to counteract the pressure causing the wall to bow.

In contrast to traditional methods, which often involve extensive excavation or wall reconstruction, carbon fiber offers a non-invasive, quick, and long-lasting solution.

The real beauty of carbon fiber is its strength-to-weight ratio. It’s five times stronger than steel, yet weighs considerably less. This means it can effectively resist the lateral pressure causing your walls to bow without adding unnecessary weight.

Additionally, it requires virtually no maintenance once installed. So, if you’re battling bowing walls, carbon fiber could be the answer you’ve been looking for.

The Carbon Fiber Installation Process

Installing carbon fiber on bowing walls is a straightforward process, but it requires precision and care. If you’re considering this solution, understanding the installation process can ease your mind and guarantee you’re ready for the task ahead.

- Preparation: First, you’ll need to prep the wall. This involves cleaning the area to remove any dust or debris that could interfere with the carbon fiber’s adhesion.

- Application: Next, an epoxy resin is applied to the wall. It’s like painting on a thick, sticky layer of glue. You’ve got to be careful here; this stuff doesn’t come off easily.

- Placement: Then, you’ll place the carbon fiber strip onto the epoxy. This part demands precision because once it’s on, it’s on. You want to make sure it’s straight and in the right position.

- Securing: Finally, you’ll apply another layer of epoxy on top. This seals the strip to the wall and gives your repair its strength.

That’s it! It’s a straightforward process, but it’s not a race. Take your time, do it right, and you’ll have a solution that’s strong, durable, and nearly invisible once painted over.

Cost of Carbon Fiber Repairs

After understanding the installation process, you may wonder about the cost of carbon fiber repairs. Well, it’s important to note that the cost can vary greatly depending on several factors.

These factors include the severity of the wall’s bowing, the size of the wall, and the specific contractor you choose. The price range typically falls between $350 to $600 per strip. However, most homeowners spend between $4,000 to $12,000 on the entire job.

Here’s the thing: while this might seem like a hefty investment, it’s vital to remember that you’re not just paying for materials. You’re also paying for a professional’s expertise and labor time.

Additionally, it’s a long-term solution that can save you from even more costly structural wall repairs down the road.

Also, keep in mind that many companies offer free estimates. So, you can get a better idea of the cost without any commitment.

Some contractors even provide payment plans or financing options to make the process more affordable. Thus, don’t let the initial cost of carbon fiber repairs deter you from investing in the stability and longevity of your home.

Potential Drawbacks of Carbon Fiber

While carbon fiber offers a robust solution for bowing walls, it’s important to keep in mind some potential drawbacks. You need to be aware that carbon fiber isn’t a one-size-fits-all solution. Its effectiveness largely depends on the specific conditions and requirements of your home.

So, you’ve got to take into account the following:

- Wall Condition: Carbon fiber is less effective on walls that are severely damaged or cracked. In such cases, alternative methods may be required.

- Limitations: It’s mainly used in straightening walls, but doesn’t work as well for horizontal or shifting problems.

- Inflexibility: Once carbon fiber is applied, it’s set for life. You can’t adjust or modify it later, which means if the issue isn’t entirely resolved, you might face difficulties.

- Aesthetics: While not a functional issue, carbon fiber strips aren’t the most attractive sight. If the wall you’re repairing is in a visible area, this could be a concern.

It’s always best to get a professional evaluation to determine if carbon fiber is the right solution for you.

Though it has its drawbacks, in the right situation, carbon fiber could be ideal.

Finding a Reliable Carbon Fiber Installer

In the face of structural problems, choosing a reliable carbon fiber installer becomes crucial. You don’t want to trust your home’s safety to just anyone. It’s important to do your research and find a reputable professional who knows the ins and outs of carbon fiber installation.

Start by seeking recommendations. Talk to friends or neighbors who’ve had similar work done. Look for online reviews, too, but remember to take them with a grain of salt. Not all feedback is impartial.

Also, don’t be shy to ask potential installers for references. A trustworthy professional won’t hesitate to provide them.

Check credentials next. Confirm they’re licensed, insured, and have relevant certifications. Don’t overlook experience either. A seasoned installer is likely to deliver quality work, which is a crucial factor in guaranteeing the success of the project.

Lastly, request quotes from several installers. While it’s tempting to opt for the cheapest offer, remember that you often get what you pay for.

Evaluate the cost against the installer’s reputation, expertise, and the quality of materials they use. A slightly higher cost might bring you peace of mind, knowing your home is in skilled hands.

Frequently Asked Questions

How Long Does Carbon Fiber Last in Wall Repair Applications?

You’re wondering how long carbon fiber lasts in wall repairs. It’s incredibly durable! You can expect it to hold up for the life of your house, typically over 50 years, barring any extraordinary circumstances.

Are There Any Environmental Impacts Associated With Using Carbon Fiber?

You’re probably thinking carbon fiber’s environmental impact is larger than a dinosaur’s footprint, right? Well, it’s not. It’s actually quite minimal, especially when compared to other wall reinforcement materials. It’s a win-win situation!

Are There Any Maintenance Requirements for Walls Repaired With Carbon Fiber?

You’ll be relieved to know, carbon fiber doesn’t require much maintenance. Once it’s applied, it’s there for good, offering reliable support. However, an occasional inspection to ascertain it’s holding up is always a wise move.

Can Carbon Fiber Be Used in Combination With Other Wall Repair Methods?

Yes, you can definitely use carbon fiber alongside other wall repair methods. It’s like adding a belt to your suspenders. It enhances the strength and longevity of the repair, giving you a stronger, more durable wall.

What Are the Indicators That My Repaired Wall Needs Additional Reinforcement?

If you’re noticing new cracks, further bowing, or shifting in your repaired wall, it might need additional reinforcement. Don’t ignore these signs! It’s essential to address any potential problems immediately to prevent further damage.

So, when your walls bow, don’t let it rain on your parade. Carbon fiber is your umbrella, shielding your home from further damage. It’s a sturdy, cost-effective solution that works fast and seamlessly integrates into your home’s design. But remember, it’s not a magic fix-all. Verify your walls aren’t too far gone and find a reliable installer. If you do, you’ll find carbon fiber isn’t just a good solution, it’s the best one for bowing walls.

Contact the Professionals at StablWall Today! (866) 782-5955

Currently, researchers are working on ways to make carbon fiber even stronger and more durable. This could mean foundations that last considerably longer than they do now, saving you money on repairs and replacements. The future may also bring us carbon fiber that’s more resistant to the elements, reducing the risk of damage from natural disasters.

Currently, researchers are working on ways to make carbon fiber even stronger and more durable. This could mean foundations that last considerably longer than they do now, saving you money on repairs and replacements. The future may also bring us carbon fiber that’s more resistant to the elements, reducing the risk of damage from natural disasters.

But, how do you evaluate if carbon fiber is worth the investment?

But, how do you evaluate if carbon fiber is worth the investment?

. This isn’t just hype; there’s a solid scientific basis. Carbon fiber’s tensile strength and ability to resist breaking under tension are among the highest of any industrial material. That means it can hold up under immense pressure, just like the kind your foundation walls face.

. This isn’t just hype; there’s a solid scientific basis. Carbon fiber’s tensile strength and ability to resist breaking under tension are among the highest of any industrial material. That means it can hold up under immense pressure, just like the kind your foundation walls face.