When a home’s foundation shows signs of distress, timely and effective repair is essential to prevent further damage. While effective, traditional foundation repair techniques often involve invasive methods such as excavation or installation of steel beams. These solutions can be expensive, time-consuming, and disruptive. Enter StablWall, a cutting-edge system that uses carbon fiber to revolutionize how foundation problems are addressed.

What is StablWall?

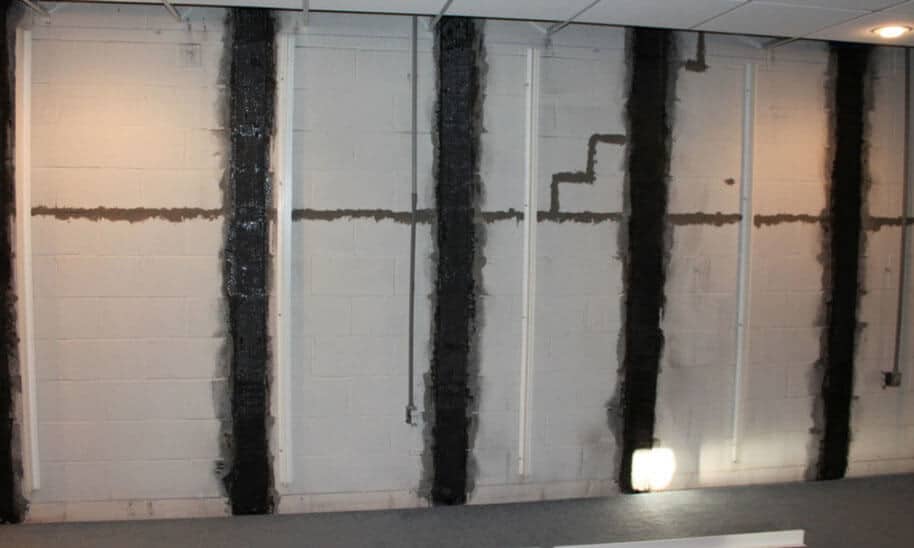

StablWall is a patented system that utilizes carbon fiber to reinforce and stabilize foundation walls. Unlike older methods that rely on heavy, bulky materials, StablWall uses lightweight carbon fiber sheets to provide unmatched strength and durability.

How StablWall Works:

- Reinforces Weak Walls: Carbon fiber sheets are bonded to the foundation wall using high-strength epoxy, creating abarrier that resists external pressures.

- Prevents Further Damage: The system stops the progression of cracks and prevents bowing walls from worsening.

- Restores Structural Integrity: Once installed, the wall regains its strength, ensuring the safety and stability of the home.

Carbon Fiber: A Material Like No Other

Carbon fiber’s unique properties make it the perfect choice for foundation repair. It is five times stronger than steel, yet it is incredibly lightweight and flexible. These characteristics allow it to stabilize walls without adding significant weight or requiring large-scale modifications.

Key Benefits of Carbon Fiber:

- Superior Strength: Carbon fiber can handle extreme tension, making it ideal for counteracting soil pressure on foundation walls.

- Resistance to Corrosion: Unlike steel, carbon fiber does not rust or degrade over time, even in moist environments.

- Lightweight and Easy to Apply: Its low weight simplifies the installation process, reducing labor and project costs.

- Longevity: Carbon fiber reinforcements can last for decades without losing effectiveness.

Applications of StablWall in Foundation Repair

StablWall is designed to address a variety of common foundation problems:

- Bowing Walls: When soil pressure causes walls to bend inward, StablWall reinforces them and prevents further movement.

- Horizontal and Vertical Cracks: The system stops cracks from spreading, restoring the wall’s strength.

- Waterproofing Support: StablWall can be used alongside waterproofing systems to ensure a dry and stable basement.

The Installation Process

One of the most appealing aspects of StablWall is its simplicity and efficiency. The system can often be installed in just one day, minimizing disruption for homeowners.

Step-by-Step Installation:

- Initial Assessment: A foundation expert evaluates the damage and determines where the carbon fiber sheets should be applied.

- Surface Preparation: The wall is cleaned to remove debris and ensure a strong bond between the carbon fiber and the surface.

- Application: Carbon fiber sheets are adhered to the wall using a durable epoxy resin.

- Curing: As the epoxy cures, it creates a permanent bond that strengthens the wall.

Why Choose StablWall?

Homeowners and contractors alike are turning to StablWall for its reliability and efficiency. Unlike traditional methods, which can involve weeks of work and significant property disruption, StablWall provides a quick and lasting solution. Its minimal impact on the home’s appearance and environment makes it a preferred choice for modern foundation repair.

StablWall represents the future of foundation repair, combining the unparalleled strength of carbon fiber with an easy-to-install system that addresses structural issues effectively. Whether it’s reinforcing bowing walls, preventing crack propagation, or supporting a comprehensive waterproofing plan, StablWall offers homeowners a durable, affordable, and non-invasive solution. By investing in this innovative technology, homeowners can ensure the stability and safety of their property for years to come.

Contact the Professionals at StablWall Today! (866) 782-5955

foundation repair kits in the market. Many homeowners opt for these DIY kits to save money. However, these kits don’t always provide great results. This is because there are various factors that should be considered in the installation of carbon fiber that you may not consider as a DIYer. The kits also aren’t the same quality as the professional-grade materials used by professional contractors.

foundation repair kits in the market. Many homeowners opt for these DIY kits to save money. However, these kits don’t always provide great results. This is because there are various factors that should be considered in the installation of carbon fiber that you may not consider as a DIYer. The kits also aren’t the same quality as the professional-grade materials used by professional contractors.