Crawlspaces and foundations are two of the most critical components of any home’s structure. Over time, these areas can suffer from a range of issues, including moisture buildup, soil movement, and structural stress, all of which can lead to cracking or bowing. While traditional repair methods like steel beams and wall anchors have been commonly used, carbon fiber wraps have emerged as a revolutionary alternative. In this article, we’ll explore how carbon fiber wraps transform crawlspace and foundation repairs, offering an efficient, durable, and cost-effective solution.

Crawlspaces are typically found beneath homes, providing access to electrical wiring, plumbing, and HVAC systems. However, they are also vulnerable to moisture, poor ventilation, and shifting soils, all of which can compromise the integrity of the foundation above them.

Common issues associated with crawlspaces and foundations include:

- Cracks in Walls and Floors: Over time, the foundation may begin to develop cracks due to soil pressure, water damage, or natural settling. These cracks can allow moisture to enter, leading to mold growth and further structural degradation.

- Bowing or Buckling Walls: In basements and crawlspaces, walls may begin to bow inward due to external pressure from water-saturated soil. This is particularly common in regions with heavy rainfall or expansive soils.

- Uneven Settling: Foundations can settle unevenly, leading to sloping floors and cracks in the walls. This is often caused by poorly compacted soil beneath the foundation or changes in moisture levels in the soil.

- Moisture and Mold: Crawlspaces are notorious for high humidity levels, which can lead to mold growth and wood rot. Over time, this can weaken the structural supports and create an unhealthy indoor environment.

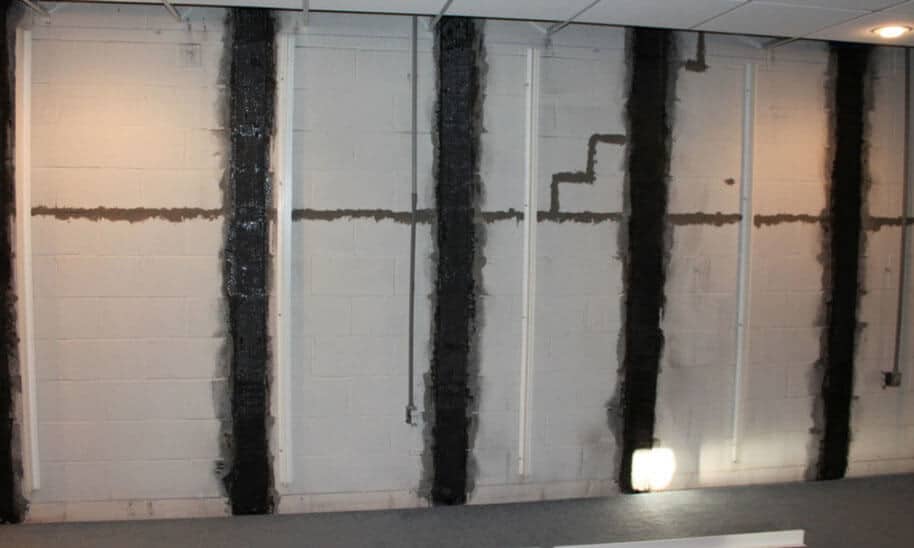

Carbon fiber wraps are used to reinforce and strengthen areas of a foundation or crawlspace that have been compromised by cracks, bowing, or other damage. The wraps consist of high-strength carbon fibers bonded with an epoxy resin, allowing them to adhere to the existing structure.

Here’s how the process works:

- Surface Preparation: The first step in the carbon fiber wrap installation is preparing the surface of the foundation or wall. This typically involves cleaning the surface and removing any loose or damaged material. If cracks are present, they may need to be filled with epoxy before the carbon fiber wrap is applied.

- Applying the Epoxy Resin: Once the surface is ready, an epoxy resin is applied to the damaged area. This resin serves as the adhesive that bonds the carbon fiber wrap to the surface.

- Installing the Carbon Fiber Wrap: The carbon fiber wrap is then applied over the epoxy-coated surface, where it is pressed into place to ensure a strong bond. In most cases, the wrap is applied vertically along the wall to provide support against bowing or cracking.

- Curing and Hardening: After the carbon fiber wrap is in place, the epoxy resin is left to cure. Once it hardens, the carbon fiber wrap becomes a permanent reinforcement for the foundation or crawlspace wall, preventing further movement or damage.

There are several advantages to using carbon fiber wraps for crawlspace and foundation repairs:

- High Strength: Carbon fiber is incredibly strong, with a tensile strength that surpasses steel. This makes it ideal for reinforcing walls that are under stress from soil pressure or structural movement.

- Lightweight and Easy to Apply: Unlike steel or concrete reinforcements, carbon fiber wraps are lightweight and relatively easy to install. This means that repairs can be completed more quickly and with less disruption to the home.

- Non-Corrosive: One of the biggest benefits of carbon fiber is its resistance to moisture and corrosion. This is particularly important for crawlspaces and basements, where high humidity levels can cause traditional steel reinforcements to rust over time.

- Minimal Disruption: Carbon fiber wraps can be applied without the need for extensive excavation or construction work, which makes the repair process faster and less disruptive for homeowners.

While carbon fiber wraps are commonly used for crawlspace and foundation repairs, they have a wide range of applications in both residential and commercial construction:

- Bowing Basement Walls: Carbon fiber wraps are often used to stabilize basement walls that have begun to bow inward due to hydrostatic pressure. The wraps are applied vertically along the wall to prevent further movement.

- Foundation Crack Repair: Cracks in the foundation can be reinforced with carbon fiber wraps, which provide a permanent seal and prevent the crack from expanding.

- Crawlspace Wall Reinforcement: In crawlspaces, carbon fiber wraps can be applied to walls that are showing signs of stress or movement. This helps prevent further damage and ensures the structural integrity of the home.

- Beam and Column Reinforcement: Carbon fiber wraps can also be used to reinforce beams and columns in areas with heavy loads or where structural supports have been compromised.

While carbon fiber wraps offer several benefits, there are some limitations to their use:

- Not Suitable for Severe Damage: In cases where the foundation has experienced severe structural damage, carbon fiber wraps may not be enough to provide the necessary reinforcement. More extensive repairs, such as underpinning or wall anchors, may be required.

- Requires Professional Installation: While carbon fiber wraps are relatively easy to apply, they require specialized knowledge and equipment to ensure proper installation. Homeowners should always work with a professional contractor who has experience with carbon fiber repairs.

Carbon fiber wraps have transformed the way crawlspace and foundation repairs are approached, offering a strong, durable, and cost-effective solution for reinforcing walls and preventing further damage. Their ease of installation, high tensile strength, and resistance to moisture make them an ideal choice for homeowners looking to address cracks, bowing, and other structural issues. As the demand for non-invasive, long-lasting foundation repair solutions continues to grow, carbon fiber wraps will remain at the forefront of modern construction practices.

Contact the Professionals at StablWall Today! (866) 782-5955